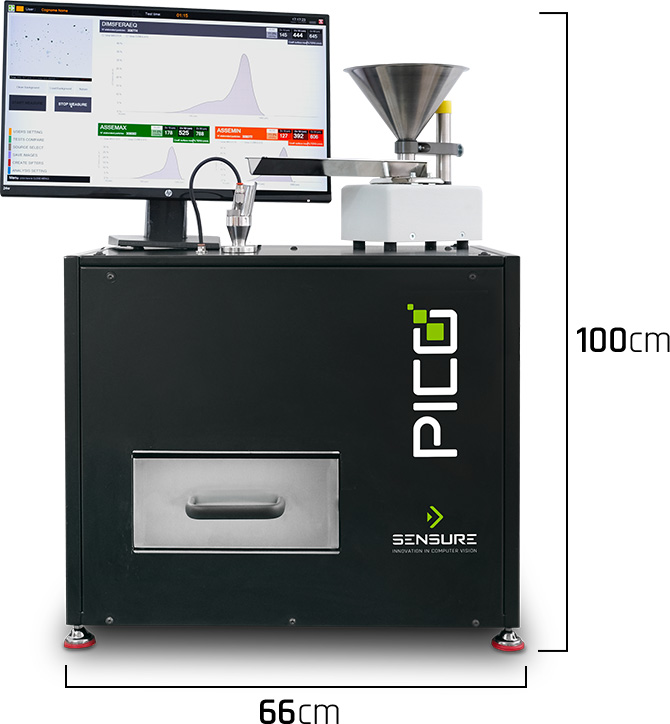

| Measurement range | from 50 micron to 2 mm |

| Sample weight | 5gr – 100gr |

| Measurement time | Proportional to the sample quantity (E.g.: a 7.5gr sample is analyzed in 1min) |

| Repeatability Measure: | 5micron (sample of 20gr, considering the parameter D (0,5)) |

| Type of measurement | Dry, in air flow |

| Accessories Required | None |

| Cleaning system | Manual or by aspirator (estimated time 10s) |

| Measurement parameters |

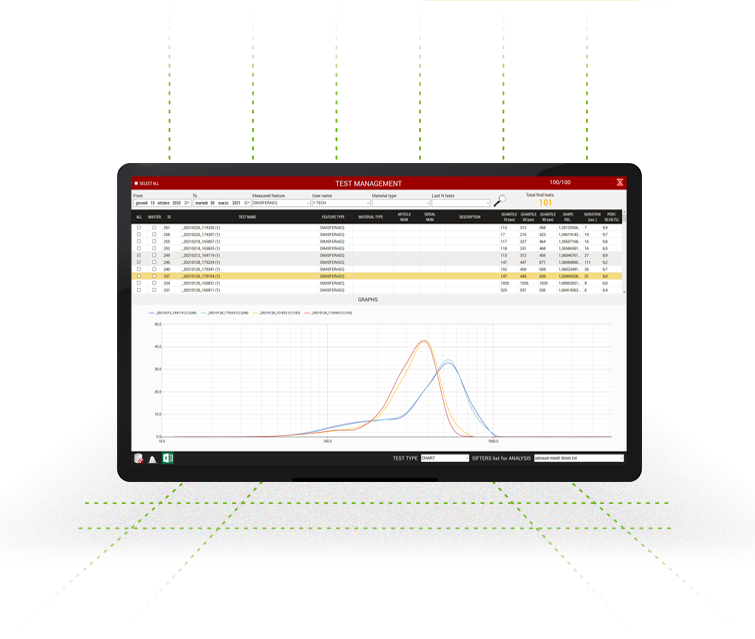

Distribution graph of the particle size by volume of

|

| Performance |

|

Sieves | Laser |

|---|---|---|---|

| Wide measurement range | |||

| Reproducibility and repeatability | |||

| High resolution for narrow distributions | |||

| Particle shape analysis | |||

| Direct measurement technique | |||

| Reliable detection of oversized grains | |||

| Robust hardware | |||

| Analysis of single particles | |||

| High measurement speed, short measuring times | |||

| Analysis of nanoparticles | |||

| Versatility (No need for adjustment) Different type of materials |

|||

| Cost | |||

| Measurement range | 50 μm - 2 mm | 10 μm - 125 mm | 10 nm - 5 mm |