Reliable, accurate, and repeatable product measurements

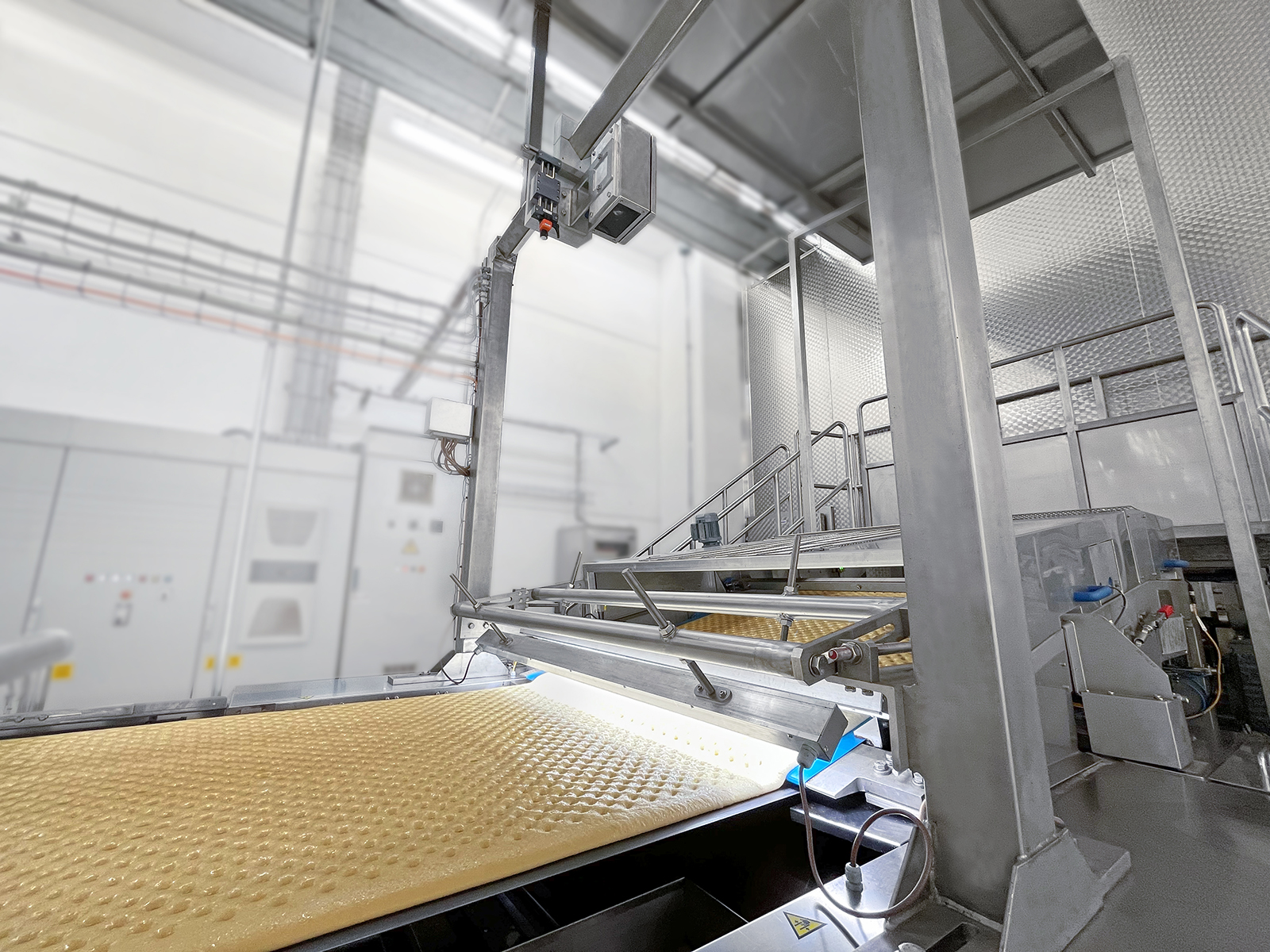

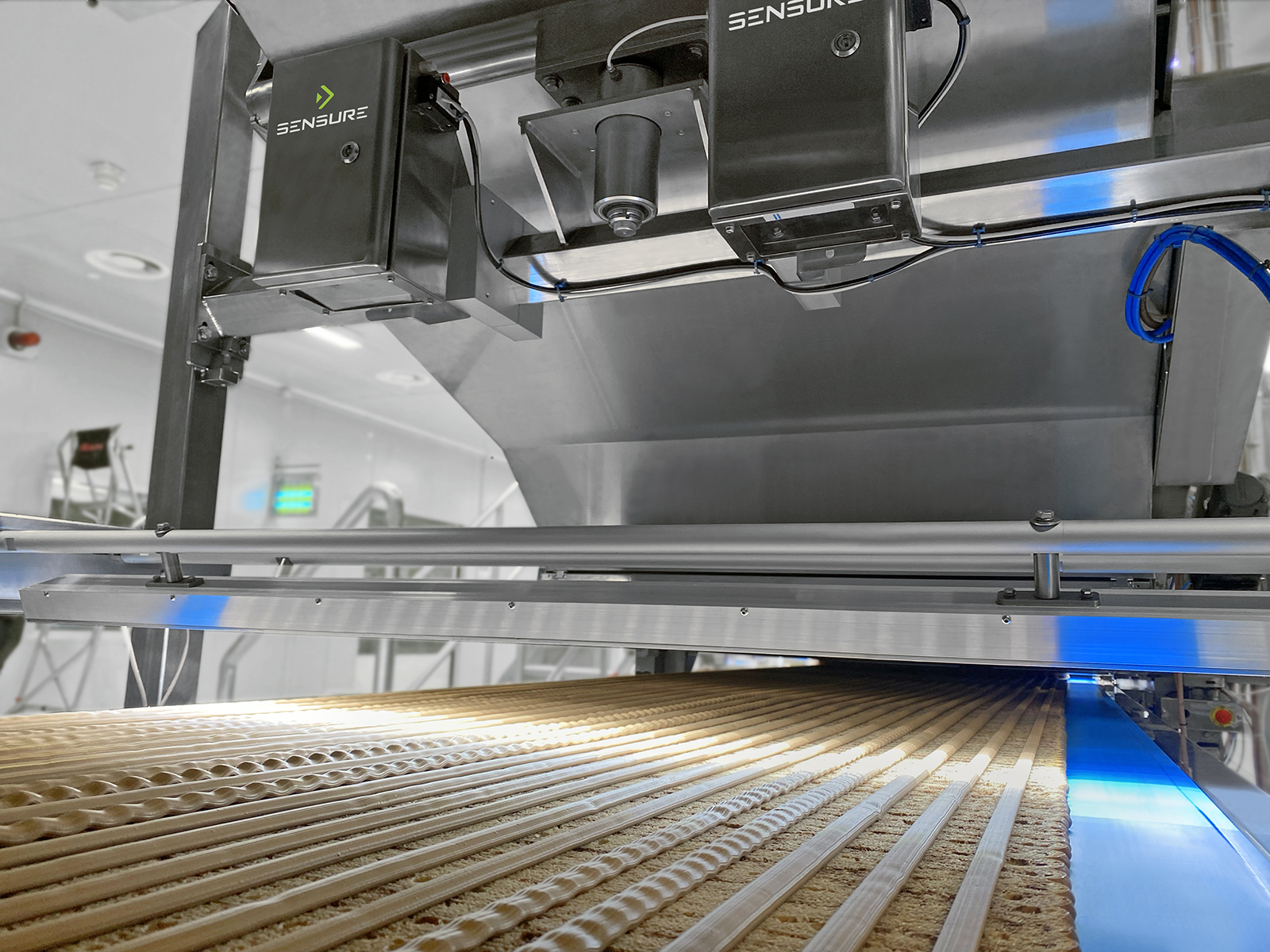

Continuous measuring of the key attributes of products (shape, size, color, thickness, volume, moisture, temperature, etc.) without contamination, before and after the different production steps (e.g. forming, proofing, baking, cooling, topping/decorating/depositing, packaging, etc.) to ensure every step is working at its best and reducing waste.

Vision hardware can operate in both the visible and non-visible spectrum with state-of-the-art components such as 2D linear or matrix cameras, 3D vision (laser triangulation, stereo vision, structured light, time-of-flight), IR/SWIR/Iperspectral cameras, thermal cameras, etc. with total control at high production speed.