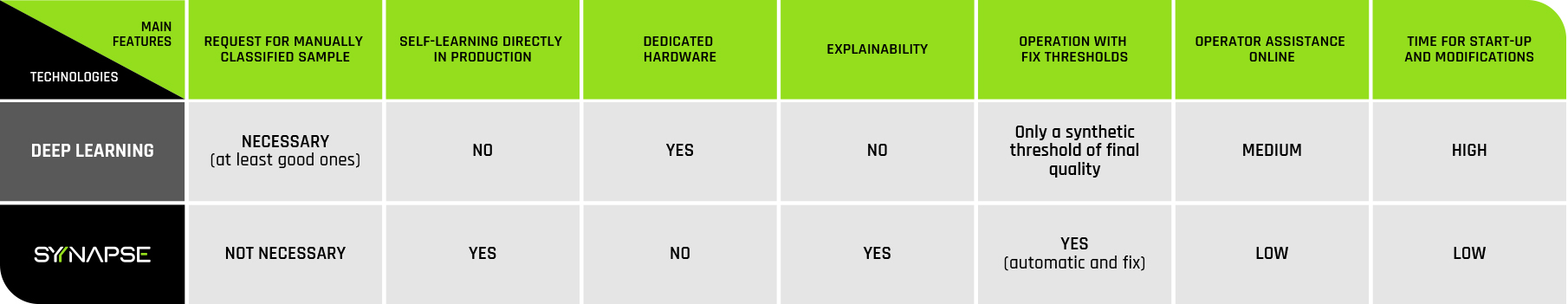

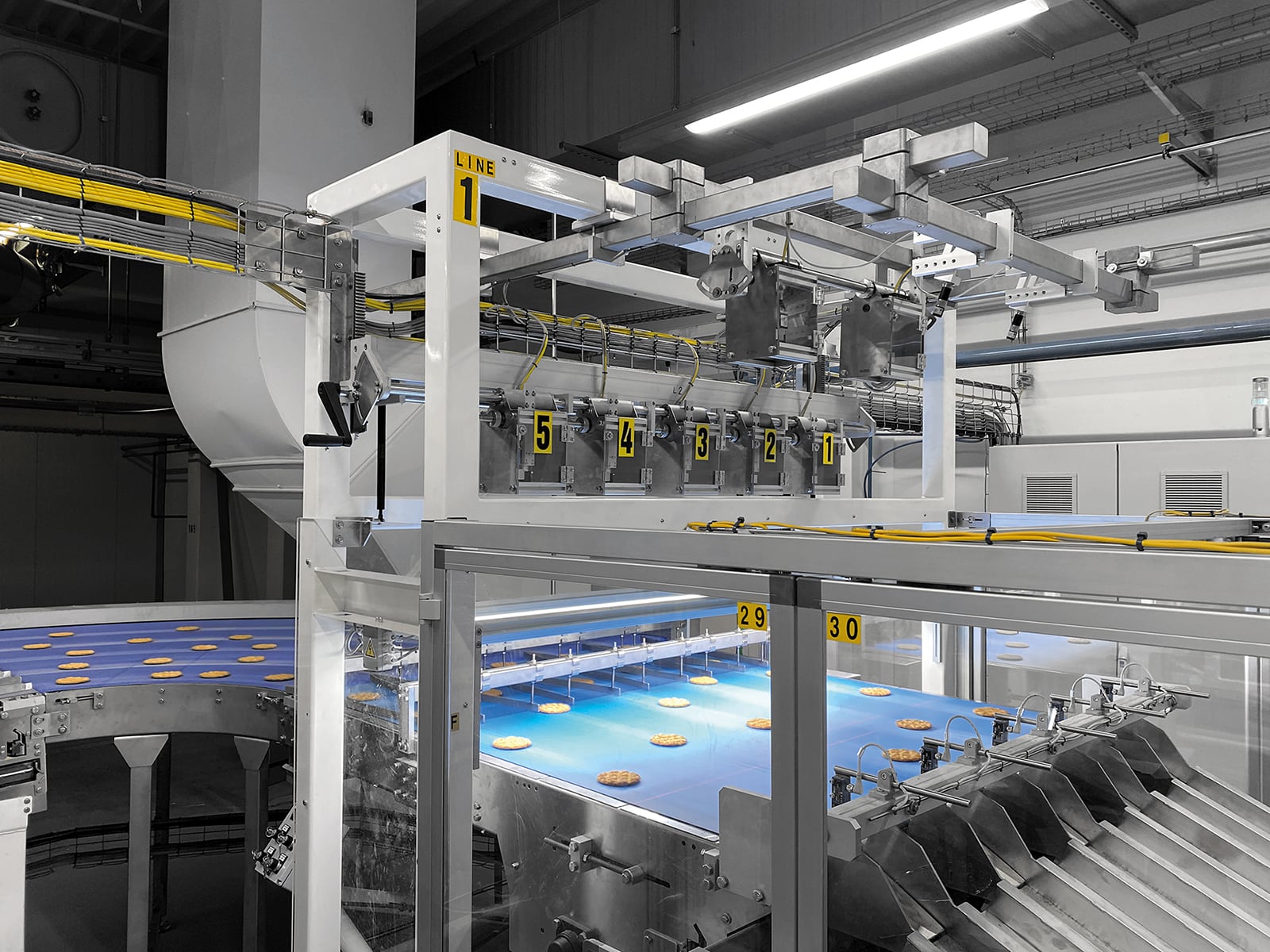

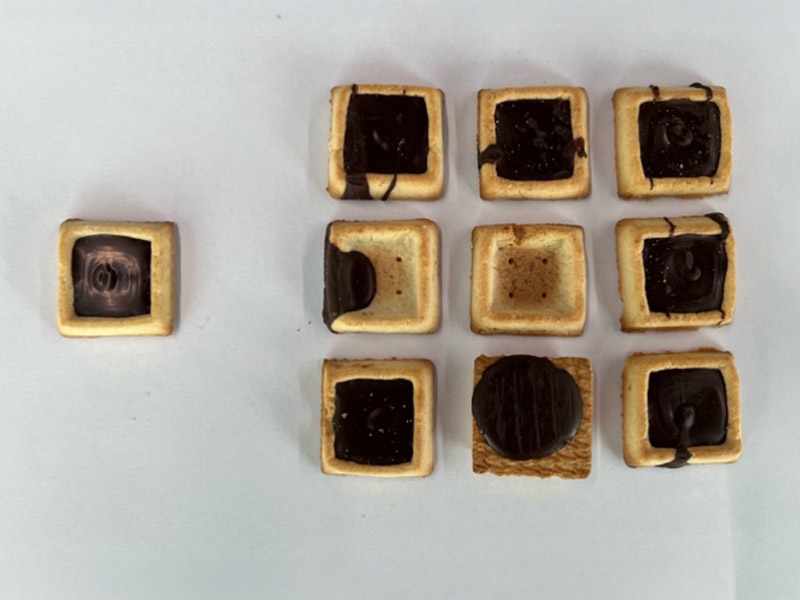

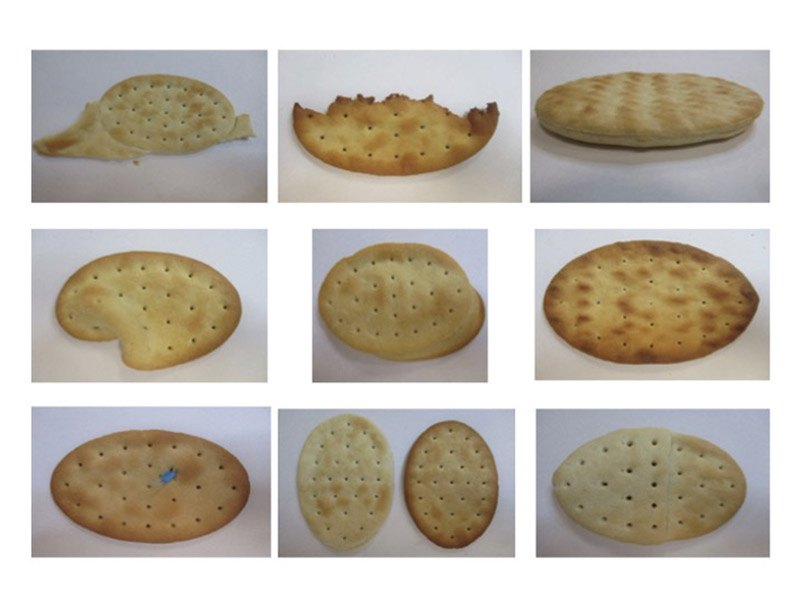

SENSURE SYNAPSE utilizes Artificial Intelligence algorithms and self-learning approach to classify products as compliant or non-compliant and identify defects and irregularities. This guarantees best-in-class quality control and maximizes packaging efficiency, even in highly variable environments, without the need for time-consuming manual classification and setup. However, the operator remains in control, with the possibility to manually adjust thresholds and select key features whenever needed, providing a flexible balance between automation and human oversight.

SENSURE SYNAPSE learns on its own, directly on the line and adapting to production variables in real-time: it automatically proposes quality recipes and tolerance limits for each identified features based on live production data, saving time and reducing human error, allowing the operator to make subsequent modification. This capability ensures operators can fine-tune and adjust thresholds or define critical features to maintain full control over the process. This brings unprecedented simplicity and control, which traditional systems cannot match.

One of the key advantages of SENSURE SYNAPSE is its transparency. Unlike other AI systems that operate as black boxes, the SYNAPSE provides clear explanations for its decisions, offering complete insight into how it determines whether products pass or fail quality checks.