Ensuring buns quality and improve the production process with SENSURE solutions

Ensuring buns quality is critical to success: to achieve this, manufacturers rely on vision inspection and monitoring systems to detect and address issues before they become larger issues.

SENSURE offers a wide range of advanced technologies that help buns producers optimize their production processes and maintain the highest levels of product quality. The systems allow for the identification of defects, even at high speed and using different technologies (2D cameras, 3D laser profilometers), and reject the non-compliant products (click here to find out what the different rejection mechanisms are).

All collected data is stored in a SQL database and are used by the SENSURE SYNAPSE software to provide customized historical reports, display and monitor live measured values, and facilitate real-time operating procedures. SENSURE analytics tools support continuous improvement activities through data analytics aimed at reducing waste, increasing plant efficiency, and enhancing process performance.

Surface Analysys (Upper part)

- Product colour – Average colour (excluding or not toppings), and edge/contour defects. Values can also be provided in L*a*b and BCU

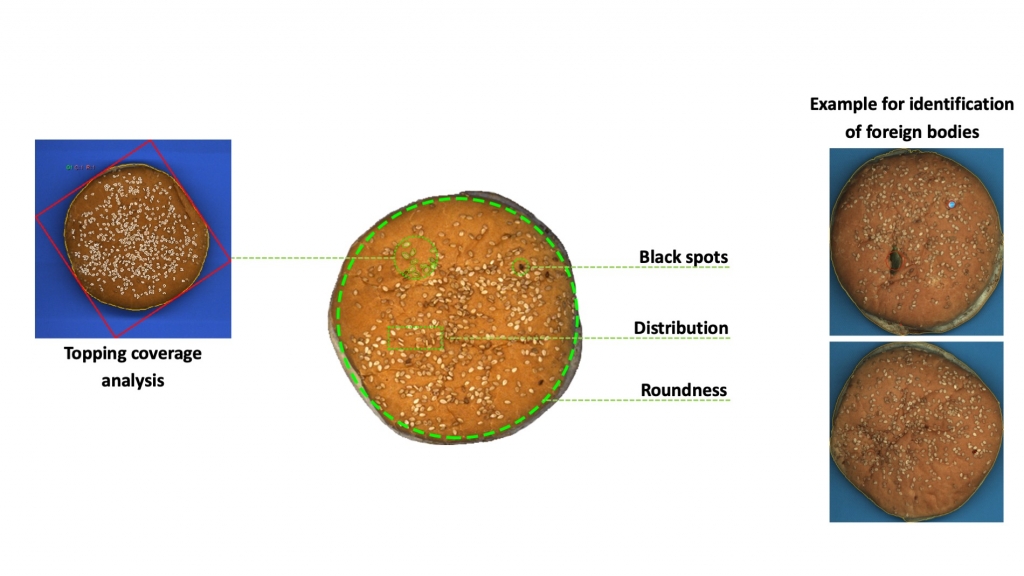

- Spots – Area calculation for white spots (i.e. blotchies, etc.), dark spots (i.e. blisters), and foreign bodies (identification is possible if the dimension and colour differences of the inclusions are detectable in the camera)

- Surface Area – Overall area calculation (to identify double/triple or broken products, etc.), cracks and holes detection

- Topping/Seeding conformity – Percentage of the surface coverage, distribution (i.e. seed voids, etc.), and colour

- Shape and Size – Min/Max/Average diameter, Min/Max axis, Roundness, Perimeter

Surface Analysys (Bottom part)

- Product colour – Average colour (excluding or not any anomalies like spots, etc). Values can also be provided in L*a*b and BCU

- White edges – Area calculation of the under-baked edges on the outer ring

- Spots – Area calculation for white (i.e. blotchies, flour, etc.), dark spots (burnt areas, etc.), and foreign bodies (identification is possible if the dimension and colour differences of the inclusions are detectable in the camera)

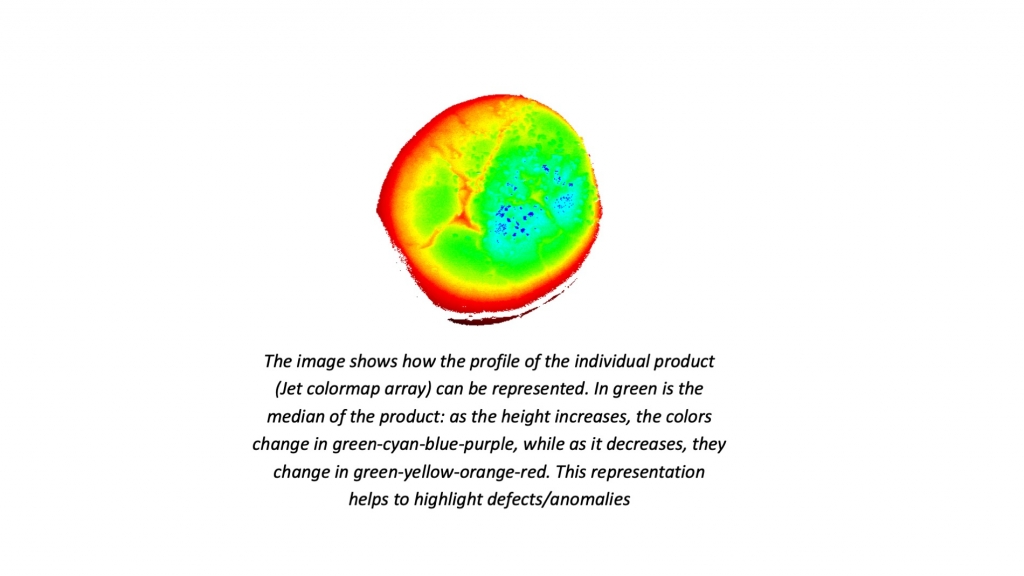

Three-Dimensional Analysis

- Slope – Curvature of the top surface of the products (Measured by calculating the difference in height between the center of the product and a user-defined ring near the product's edge), flatness, and planarity

- Height – Min/Max peaks, average heights, etc.

- Volume