Vision inspection systems for the warehouse logistics - The Tosano Group case history

The Tosano group was born in 1970. A small family-run supermarket is today, with its 18 hypermarkets and 4.000 employees, one of the most best-known and fastest growing names in north-east Italy.

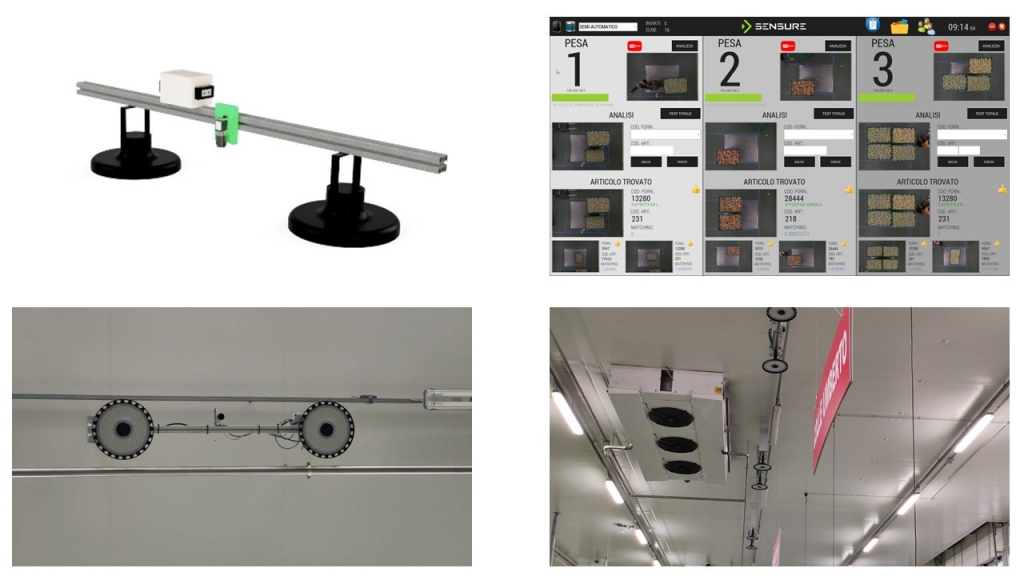

For the automatic recognition of fresh fruit and vegetables packages on pallets at the entrance and in transit of the automated warehouse, the Tosano group has entrusted the competence and experience of SENSURE, a company that has been designing and develops vision inspection systems for the control of high variable products.

The three vision inspection systems, installed at four meters from the ground and each consisting of camera and dedicated lights, allow to inspect the upper surface of the fresh fruit and vegetables at the entrance of the warehouse during pallet weighing phase: thanks to image processing and matching algorithms, the software is able to recognize whether the examined goods are correctly present in the list of goods scheduled with the ongoing delivery by the specific supplier. By connecting to the company ERP, the system takes advantage of the information of the goods expected by the supplier. The intrinsic variability of vegetables and fruit, also typical of the different seasonality, require, for their accurate recognition, of innovative approaches based on the images processing and machines learning algorithms.

The system is also able to express a doubt among several different packages, in order to help the operator in choosing the correct product. The resolution of the doubt will be stored to gradually increase the system detection capacity over time.

In the case of packages identified not correctly by the vision system, the operator makes a simple correction. Upon confirmation of the operator, the stored data are however updated to improve the automatic detection of the system more and more.

The application has positive implications in the handling of goods, significantly improving the control of traceability and identification of errors in shipments and automating the control process at the entrance of the warehouse by reducing the data entry time in the ERP.

The technology has also been applied to the control of the packaged goods in transit in the automatic warehouse for the final shipment.