COMPLETE AND CUSTOMISED VISION INSPECTION SYSTEMS

Thanks to the modular and customised hardware of SENSURE STARGATE and with the SENSURE SYNAPSE software suite, it is possible to configure a complete on-line vision inspection system that fulfils any operational requirements, even on already existing lines. The SENSURE STARGATE can be tailored to suit the specific application and production line.

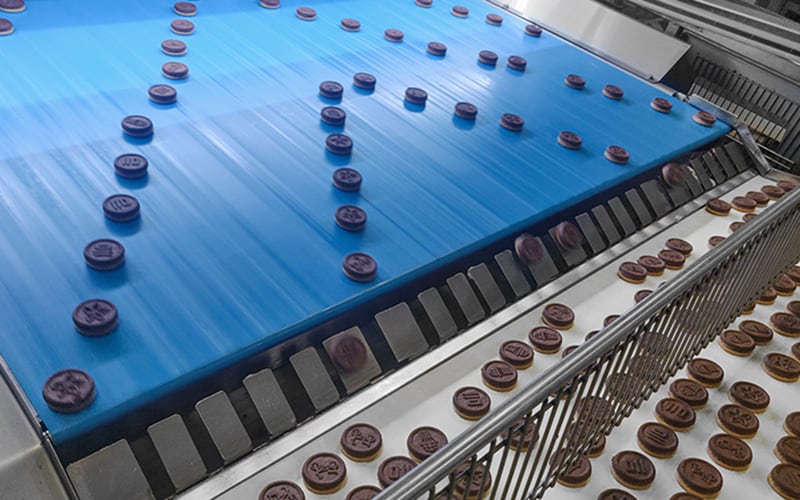

In addition to the development of customized systems tailored to various production lines (speed, available space, etc.) and the products to be managed (dimensions, placement on the line, etc.), SENSURE has standardized two complete solutions that can be installed in lines with products arranged in a single row (STARGATE SL-C) or in multiple rows (STARGATE ML-C).