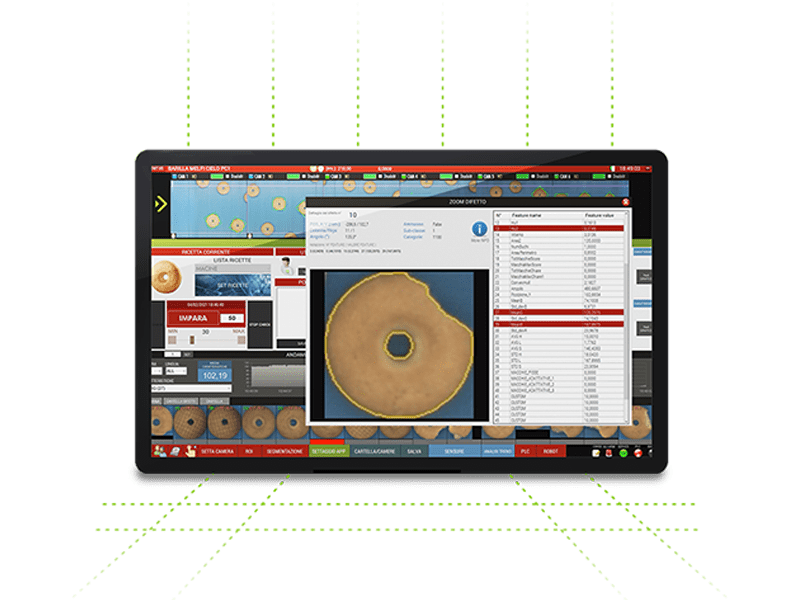

With SENSURE SYNAPSE, it is possible to measure numerous product features (a wide set is included in the system), such as shape, size, and colour, using 2D technology (industrial camera) and perform a full 3D product profile using 3D technology (laser profilometer). Thanks to the use of thermal imaging and infrared cameras, it is also possible to identify features in addition to the visible ones. SENSURE SYNAPSE can also be configured to analyse features thought to be impossible to manage, such as pattern variations, topping conformity, average colour, slope, and much more, even on the bottom parts of the products.

Using SENSURE SYNAPSE ensures reliable, repeatable, and accurate measurements, even at high line speed, with the added benefit of all data being saved in a SQL database.

The SENSURE SYNAPSE system is flexible and can be customized to meet specific needs through the development of additional features after a feasibility analysis. Additionally, SENSURE solutions can be integrated with third-party systems like metal detectors, checkweighers, moisture analysers, ovens, etc.

With product data and the application of artificial intelligence, there is potential to enhance a brand's reputation through improved product quality (SYNAPSE QUALITY).

Quality-related information can be conveyed to systems (e.g., robots, etc.) for automatic non-compliant product management (SYNAPSE GUIDANCE), enabling comprehensive process control through product data analysis (SYNAPSE DATA ANALYTICS).