One of the major Italian biscuits’ producers relies on SENSURE for in-line quality inspection system

The bakery industry has become extremely competitive: consumers continue to expect high quality products, while manufacturers want to achieve economic production.

The Customer, one of the major Italian biscuits' producers, approached SENSURE to automate the quality control and rejection of non-compliant products on two existing different lines. The proposed perfect solution? SENSURE STARGATE ML-C.

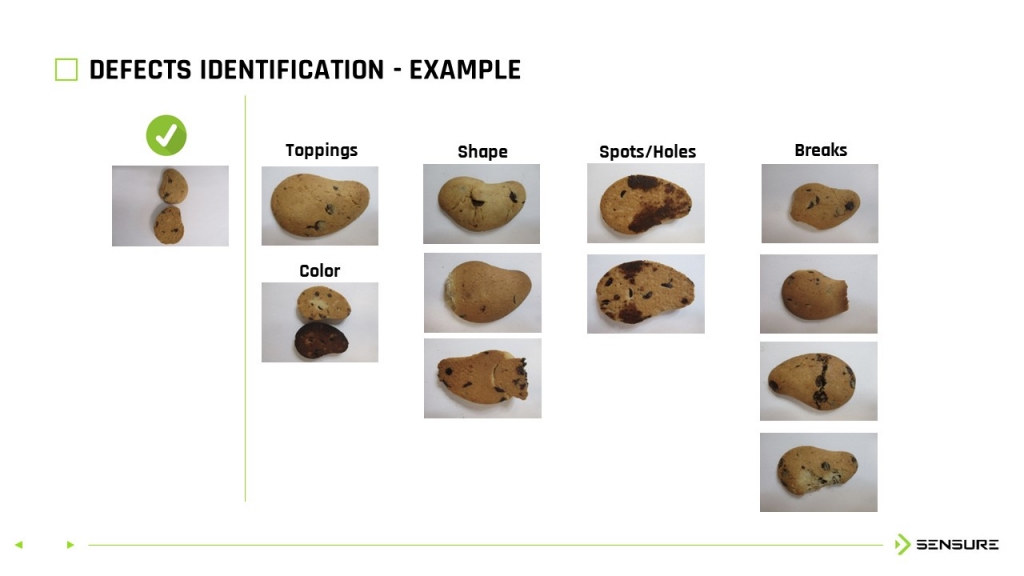

Compared to standard vision inspection systems, SENSURE STARGATE ML-C is a compact and solid system with the ability to perform 2D (from top and bottom) and 3D measurements to identify defects in size, shape, colour, surface texture and volume which permit the single rejection of non-compliant products (with air nozzles) or agglomerated products (with trap).

The installed solutions also guarantee continuous monitoring of the process with data collection and analysis, providing a real-time display and dedicated reporting. SENSURE, in accordance with the Customer's requests, has also installed, in different points of the line, monitors with dedicated information (product size, colour trends, etc.) useful for monitoring the process along the line and preventing any issues which may occur.

Thanks to the technical solutions adopted on STARGATE ML-C, the installation of the systems was very fast, guaranteeing production start-up in a few days, thus making the system easily installed even on existing lines like for the Italian customer. Thanks to the self-learning SENSURE SYNAPSE operation, the start-up of the vision system took place during normal line operation.

If you want to find out more about the SENSURE STARGATE ML-C solution, visit the webpage at the following link (click here).

The two solutions installed have the following main specifications and allow the control of 25 different types of biscuits:

LINE 1

Belt width: 1.600 mm

Belt speed: 25 m/min

Number of rows: 32

Analysis type: 2D (top and bottom)

Vision points: 5 (top) + 2 (bottom)

Rejection: 32 single air nozzles and 5 traps

LINE 2

Belt width: 1.250 mm

Belt speed: 25 m/min

Number of rows: 24

Analysis type: 2D (top and bottom)

Vision points: 3 (top) + 2 (bottom)

Rejection: 28 single air nozzles and 4 traps